Industrial Process Chillers

Industrial Process Chillers

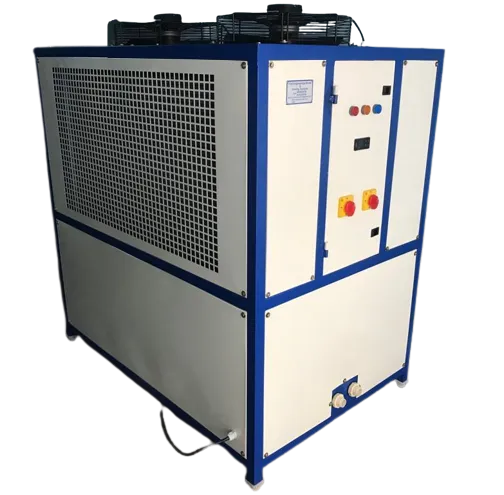

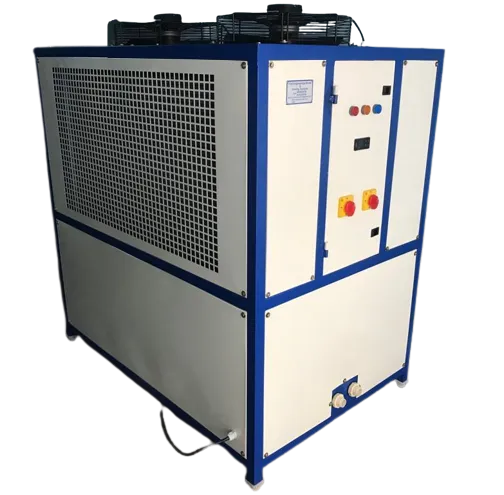

Our process chillers are custom-built to match your load profile, utilities, and plant environment. Whether you need closed-loop cooling for hydraulic oil, glycol circuits, or process water, every skid combines heavy-duty compressors, oversized condensers, and PLC-based controls for round-the-clock stability.

PSN Chillers offers Process Chiller for medical and various Industrial application like printing, plastic mould cooling, lamination processes, laser cutting cooling. Our process chiller are highly energy efficient apart from being extremely compact.

Process Oil Chiller

A Process Oil Chiller is a cooling system designed specifically to maintain precise temperature control of oils and heat transfer fluids in industrial processes. It circulates cooled oil through your equipment (molds, bearings, gearboxes, or presses) to remove excess heat and stabilize operating temperature.

Features

- Long-life emerson copeland compressor designed for heavy-duty refrigeration services.

- Energy efficient air/water cooled compact chillers, suitable for working in high ambient conditions.

- Inner tank has a capacity of 100-200 LTR

- Fully puff insulated tank

- Cooling capacity stays longer

- Maintenance free high volume, high pressure water circulation pump.

Applications

- Food (Milk and Dairy, Beverages, Confectionery, Chocolate, Storage)

- Plastics (Injection, Blow Moulding, Extrusion, Film Extrusion, thermoforming)

- Laser (Welding, Profiling, Cutting, Optics, Medical, Marking, Aesthetics)

- Paper (Manufacturer, Printing, Card Board, Labels, Plastic Film)

- Chemical (Petro chemical, Paints, Solvents, Temperature Control)

Benefits :

- Compact Size

- High Performance

- Extremely low noise

- High cooling capacity

- High energy efficiency

- Anti-freeze Protection

- High efficient copper tube condenser

- Easy to operate and long lasting service

Capacity Range :

2 TR - 10 TR and above as per the requirements.

Safety :

High and Low pressure protection, overload protection, high and low voltage protection, single phase preventer

Process Water Chiller

A Process Water Chiller is a cooling unit that circulates chilled water through industrial systems to absorb and carry away heat generated by manufacturing processes. It is ideal in cooling tools, molds, CNC machines, lasers, printing presses, and more.

Features

- Long-life emerson copeland compressor designed for heavy-duty refrigeration services.

- Energy efficient air/water cooled compact chillers, suitable for working in high ambient conditions.

- Inner tank has a capacity of 100-200 LTR

- Fully puff insulated tank

- Cooling capacity stays longer

- Maintenance free high volume, high pressure water circulation pump.

Applications

- Food (Milk and Dairy, Beverages, Confectionery, Chocolate, Storage)

- Plastics (Injection, Blow Moulding, Extrusion, Film Extrusion, thermoforming)

- Laser (Welding, Profiling, Cutting, Optics, Medical, Marking, Aesthetics)

- Paper (Manufacturer, Printing, Card Board, Labels, Plastic Film)

- Chemical (Petro chemical, Paints, Solvents, Temperature Control)

Capacity Range :

2 TR - 10 TR and above as per the requirements.

Benefits :

- Compact Size

- High Performance

- Extremely low noise

- High cooling capacity

- High energy efficiency

- Anti-freeze Protection

- High efficient copper tube condenser

- Easy to operate and long lasting service

Safety :

High and Low pressure protection, overload protection, high and low voltage protection, single phase preventer

Process Glycol Chiller

A Process Glycol Chiller is designed to cool a glycol-water mixture (often propylene or ethylene glycol) used in systems where water alone might freeze, corrode, or be unsuitable. It circulates the glycol mixture to maintain controlled low temperatures in processes like beverage cooling, freeze dryers, VFD cooling, or cold rooms

Features

- Long-life emerson copeland compressor designed for heavy-duty refrigeration services.

- Energy efficient air/water cooled compact chillers, suitable for working in high ambient conditions.

- Inner tank has a capacity of 100-200 LTR

- Fully puff insulated tank

- Cooling capacity stays longer

- Maintenance free high volume, high pressure water circulation pump.

Applications

- Food (Milk and Dairy, Beverages, Confectionery, Chocolate, Storage)

- Plastics (Injection, Blow Moulding, Extrusion, Film Extrusion, thermoforming)

- Laser (Welding, Profiling, Cutting, Optics, Medical, Marking, Aesthetics)

- Paper (Manufacturer, Printing, Card Board, Labels, Plastic Film)

- Chemical (Petro chemical, Paints, Solvents, Temperature Control)

Capacity Range :

2 TR - 10 TR and above as per the requirements.

Benefits :

- Compact Size

- High Performance

- Extremely low noise

- High cooling capacity

- High energy efficiency

- Anti-freeze Protection

- High efficient copper tube condenser

- Easy to operate and long lasting service

Safety :

High and Low pressure protection, overload protection, high and low voltage protection, single phase preventer

Customized Industrial Process Chillers

We manufacture our products as per our clients needs.Our customization capability has helped us in achieving our ultimate goal of client satisfaction. We do all kinds of customaizations like size, dimension and volumn etc., to fit the requirements of our clients.